PAPER FOR CORRUGATED BOARD

Specialists in Strength

Cellulose fibres is a major cost for paper manufacturers. One way to decrease the amount of fibres needed in paper and paperboard is by improving the strength properties of fibres. Greater fibre strength can be achieved by a process called crosslinking. JSS Teams has developed FiberMax™ CDI20, a hi-tensile copolymer dry strength agent specifically for paper making, in particular for kraft liner board and corrugating medium. This product works by cross linking fibres, in particular recycled paper fibres, through formation of chemical links between molecular chains to form a three-dimensional network of connected molecules. The stronger the covalent bonds the stronger the paper. FiberMax™ CDI20 can be used to reduce the amount of pulp fibre required to make the paper as well as increase paper strength, and is added via a dosing pump to the header mixing box or mixed in the batch system. JSS Teams uses its proprietary process of resin polymerisation to produce this product in its facility in Bangkok, Thailand.

Features

- High quality corrugator medium paper and kraft-liner paper

- Ability to reduce AKD and DSR (Dry strength Resin) usage in batch

- Increased Ring Crush Test (RCT)

- Increased Tensile strength

Benefits

- Better quality means better yields and less waste

- Less outlay in other functional additives such as AKD and fillers for sizing

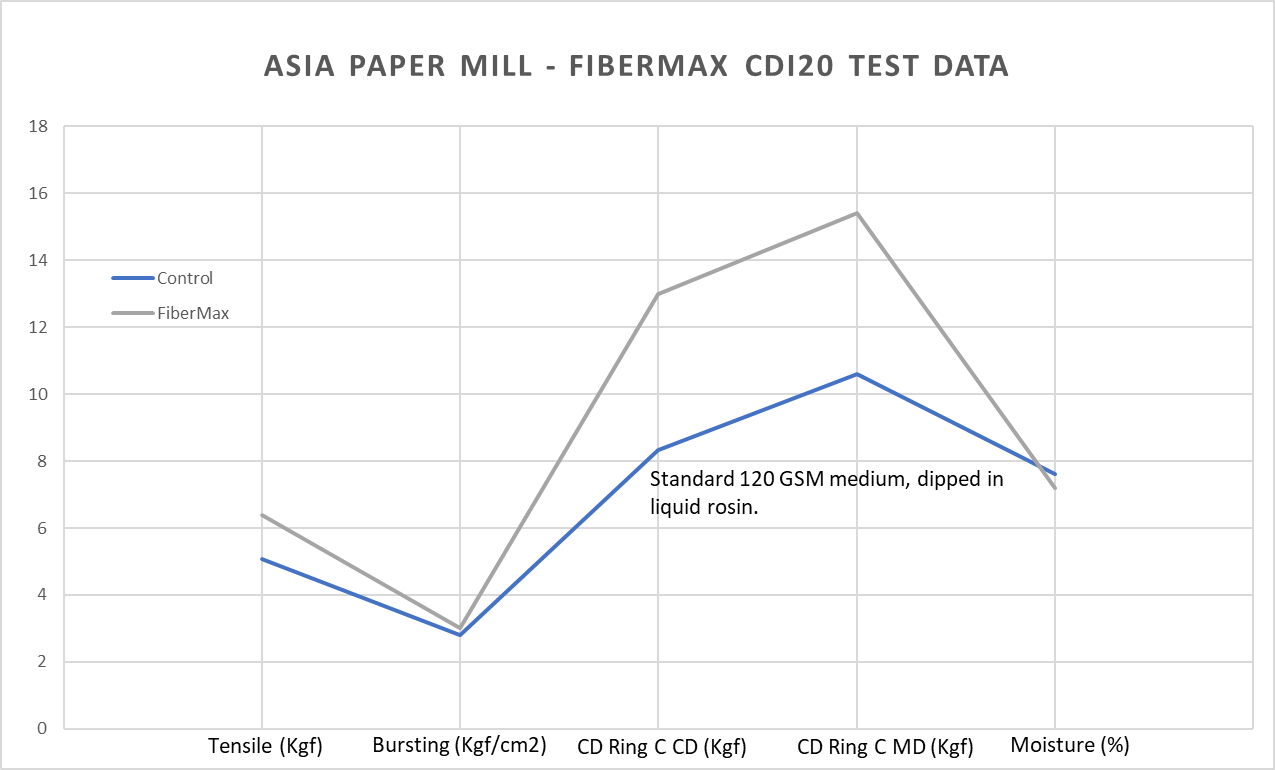

- Increased strength in paper. in a paper mill trial in Asia, results increased Ring Crush by more than 40% and tensile by 26% vs control – see chart (note results will vary between mills and machines)

- Reduce use of existing DSR (Dry Strength Resin)

- Save operating costs from tear outs of paper by increasing tear resistance (tensile)

Packaging

- 1,000kg Bulk